How does Paper Sheeting Machine work?

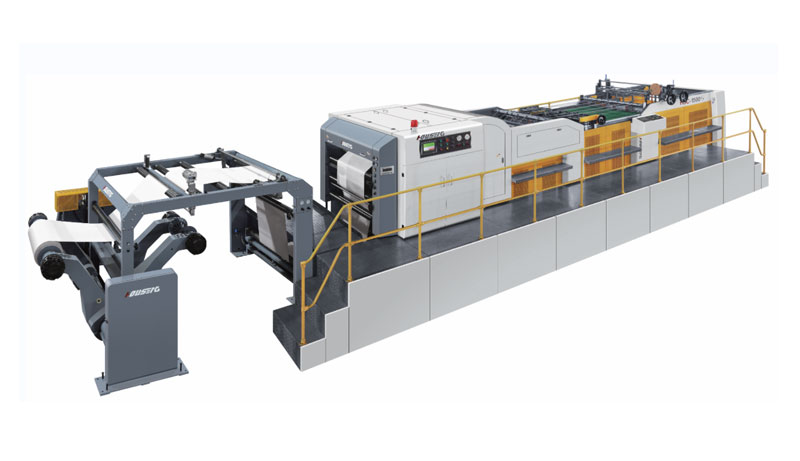

A paper sheeting machine, also known as a paper cutter or sheeter, is a device used to cut large rolls or sheets of paper into smaller, more manageable sizes.

What is the working principle of the paper cutter?

1. Feeding

The paper roll or sheet is loaded onto the machine, either manually or through an automated feeding system.

The feeding mechanism ensures a continuous and controlled supply of paper for cutting.

2. Unwinding

If the paper is in roll form, the machine unwinds the paper roll and guides it towards the cutting section.

Tension control mechanisms ensure proper paper tension throughout the process.

3. Alignment

The paper is aligned to ensure it is in the correct position for cutting.

This is typically done using edge guiding systems, sensors, or optical alignment systems. Proper alignment is crucial for accurate and consistent cuts.

4. Cutting

The cutting mechanism is engaged to perform the actual cutting.

There are different types of cutting mechanisms depending on the specific machine:

(1) Rotary Sheeter

A rotary shear uses a rotating knife cylinder with multiple blades to cut the paper. The paper passes between the rotating knife cylinder and a bed knife, which creates the desired cut.

(2) Guillotine Sheeter

A guillotine shear employs a moving knife blade that comes down onto the paper to perform the cut. The paper is held in place, and the knife blade moves across the width of the paper, making a clean cut.

(3) Laser Sheeter

Some advanced sheeting machines use lasers to perform the cutting. The laser beam follows a predetermined path guided by computer software, resulting in precise and clean cuts.

5. Separation

After the cut is made, individual sheets need to be separated from each other. This can be done using air blasts, vacuum systems, or mechanical separation devices, depending on the machine's design.

6. Stacking/Delivery

The cut sheets are then either stacked in neat piles or delivered to an output conveyor or collection tray, depending on the machine's configuration. Some machines may include stacking mechanisms to ensure proper sheet alignment and prevent damage.

7. Control System

A paper sheeting machine typically incorporates a control system that regulates and monitors the machine's operation.

It includes features such as automated cutting length adjustment, speed control, and safety mechanisms.

Summarize

paper sheeting machine typically utilize sensors, cameras and computer controls to monitor and adjust cutting parameters to ensure accurate and consistent paper sizes.

And some paper sheeting machine may have additional functions, such as waste removal systems, quality inspection systems or integration with downstream processes, determine whether you need them before purchasing.