How to Choose the Right Paper Sheet Cutter for Your Production Needs?

The right paper sheet cutter isn’t just a piece of equipment—it’s the backbone of consistent efficiency and product quality. Whether you’re handling packaging materials, printing papers, or specialty cardstocks, choosing a cutter that aligns with your unique production rhythm can eliminate bottlenecks, reduce waste, and boost your bottom line. The key lies in moving beyond generic specifications to a targeted evaluation that ties every feature to your actual workflow.

Define Your Core Production Requirements

Before diving into technical specs, map out your non-negotiable needs—this foundational step prevents costly mismatches. Capacity scale is your first checkpoint: a small-batch printing shop won’t benefit from the same high-volume cutter as a large packaging manufacturer, just as a facility processing 10,000 sheets daily can’t rely on a semi-manual model. Next, focus on cutting dimensions. The ideal paper sheet cutter should cover the 400-1650mm range, a sweet spot that accommodates most standard and custom paper sizes, from A4 sheets to large-format packaging blanks.

Paper type also dictates your choice. Thin, delicate tissues demand a cutter with gentle handling to avoid tearing, while thick corrugated boards require robust blade pressure. Specialty papers, such as coated or textured stocks, may need adjustable clamping systems to maintain precision without leaving marks. By linking these factors—capacity, size range, and paper variety—you narrow down options to those that fit your daily operations, not just theoretical performance.

Filter by Critical Parameters: Speed, Precision, and Automation

Once your needs are clear, evaluate technical parameters that directly impact productivity. Cutting speed, measured in sheets per minute (SPM), should align with your throughput goals—but never at the expense of accuracy. A high-speed cutter that sacrifices precision will only create rework, eroding efficiency. Precision error is equally non-negotiable; look for models with a margin of error under 0.1mm, especially if your products require tight tolerances for subsequent processes like folding or printing.

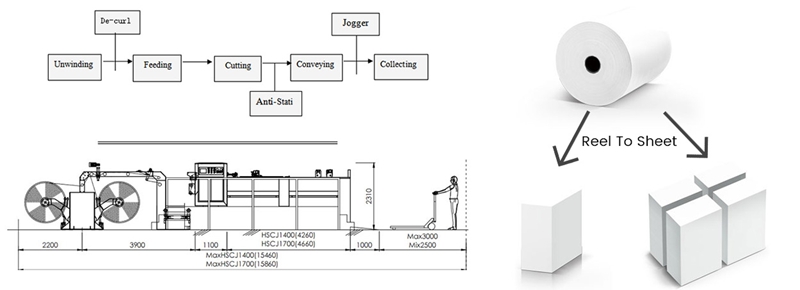

Automation level is the third pillar. Fully automated paper sheet cutters integrate feeding, alignment, cutting, and sorting, minimizing human intervention and reducing labor costs. Semi-automated options, which require partial manual input, may suit smaller operations or those with variable job requirements. Consider your labor resources: if you face staffing shortages, automation becomes a strategic investment, not a luxury. These three parameters work in tandem—prioritize balance over single-feature excellence.

Match Functions to Practical Scenarios: Maximize Utility

Modern paper sheet cutters offer up to 9 optional functions, each designed to solve specific production challenges.Coding is essential for traceability, ideal for industries like food packaging where batch numbers or expiration dates are mandatory. Automatic feeding systems shine in high-volume environments, ensuring consistent material flow and reducing downtime from manual loading. Weighing functions are a boon for operations that need precise sheet counts or material weight verification, such as pharmaceutical leaflet production.

Other valuable features include edge trimming for uneven paper stock, dust extraction to maintain a clean workspace, and batch programming for repetitive jobs. The key is to avoid “feature overload”—select functions that address your current pain points and have room to grow with your business. A cutter with customizable function packages lets you pay for what you need while keeping future expansion options open.

Prioritize Quality Certifications: Ensure Reliability and Compliance

Quality certifications are non-negotiable indicators of a paper sheet cutter’s performance and safety. Look for models with ISO9001 certification, which confirms adherence to international quality management standards. CE certification ensures compliance with European safety, health, and environmental requirements, while CSA certification is critical if you operate in North America. These certifications aren’t just logos—they mean the cutter has undergone rigorous testing to meet industry benchmarks, reducing the risk of breakdowns and ensuring compliance with regional regulations.

Certified equipment also tends to have longer lifespans and better resale value, as they’re built with durable components and standardized manufacturing processes. For global operations, multi-certified cutters eliminate the hassle of sourcing region-specific equipment, streamlining your production line across locations.

Take Action to Elevate Your Production

Are you ready to choose the right paper cutter now? There are several models of machines that meet the above requirements. Contact HAOSHENG and let it recommend the most suitable machine for you!

AI Content Identification: This article contains less than 30% AI-generated content, with core insights and practical guidance provided by industry experts.