1.HSC-S series Twin Knife Paper sheeting machine adopts advanced design of synchronic rotary which are driven directly by high power AC servo motor with high accuracy and clean cut.

2.And using our patent with embedded cutting head design, that its cutting cross profile is straight and not pulling out fibers, this is key point to eliminate hairs of paper. Widely used for cutting cardboard, coated paper, Kraft paper, culture paper, art paper, duplex,packaging paper, etc. up to 1000gsm.

3.HOUSENG Twin Knife Paper sheeting machine is dedicated to produce sheet cutter , Products are well used and verified by almost all top cosmetics and pharmaceutical packaging customers, and promise their is no risk for long term running of your products in future. Consider this kind of machine to improve quality and save cost, To improve efficiency .

cardboard paper, coated paper, kraft paper, cultural paper, writing paper, double gummed paper, gloss photo paper, gold and silver cardboard, aluminum paper, laser paper, packaging paper etc.

HSC-S Twin Knife Paper sheeting machine series run with high precision, stable operation, low energy consumption and high effciency, are developed by technology from German and decades years of experience we have. lt's widely used in the paper industry and printing industry.

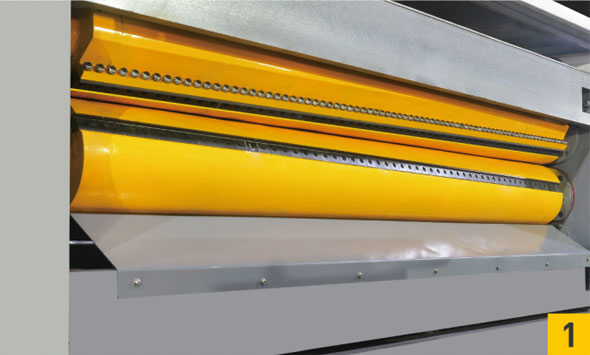

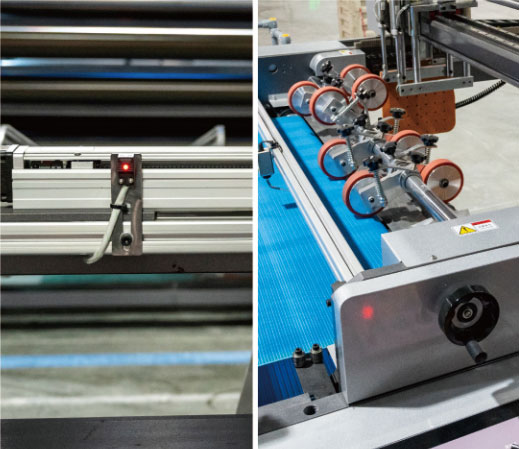

Double rotary spiral cutter rollers can cut paper clearly in less force; German precision bearing and cutting knife achieve high cuting precision; Touch interface control is easy to operate: The reasonable infection device can remove the cured paler effectively, thus strenath tension ofthe paper rol. heets can directly into printing without trimming after cutting, which do improve economic effciency,reduce production costs

|

Double Rotary Sheeter Group Precision rotary sheeter groove is processed byimported advanced |

|

|

Electric Control Part German imported Siemens PLC and The United States Emerson servo |

|

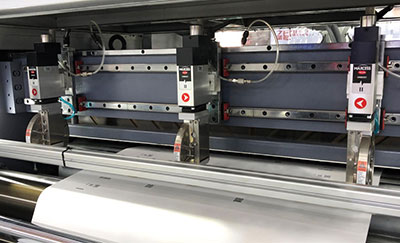

Slitting Knife Top shear air knife innovative desian enables pneumatic movement of |

|

|

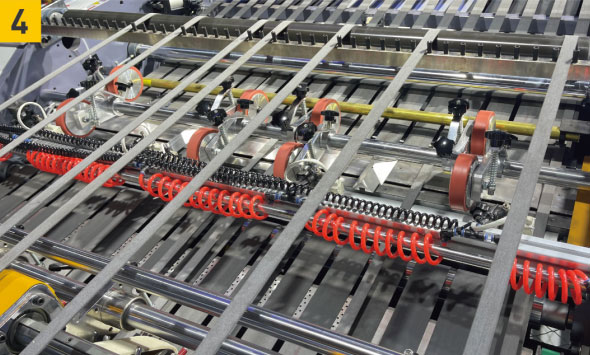

Conveying Overlap Part A precision structure can adjust the synchronous deceleration wheel, |

According to HOUSENG MACHINE, are mainly used for paper cutting in Paper Mill, Printing House and etc.

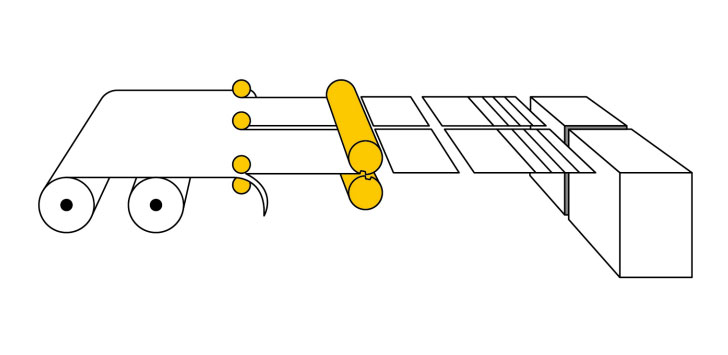

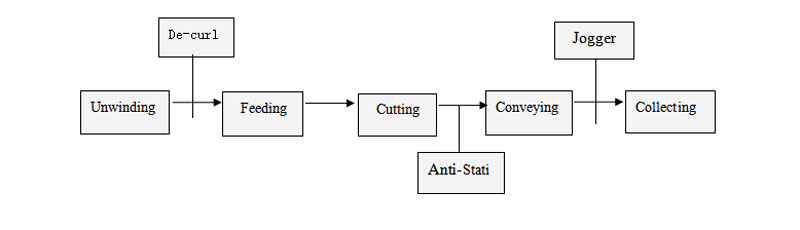

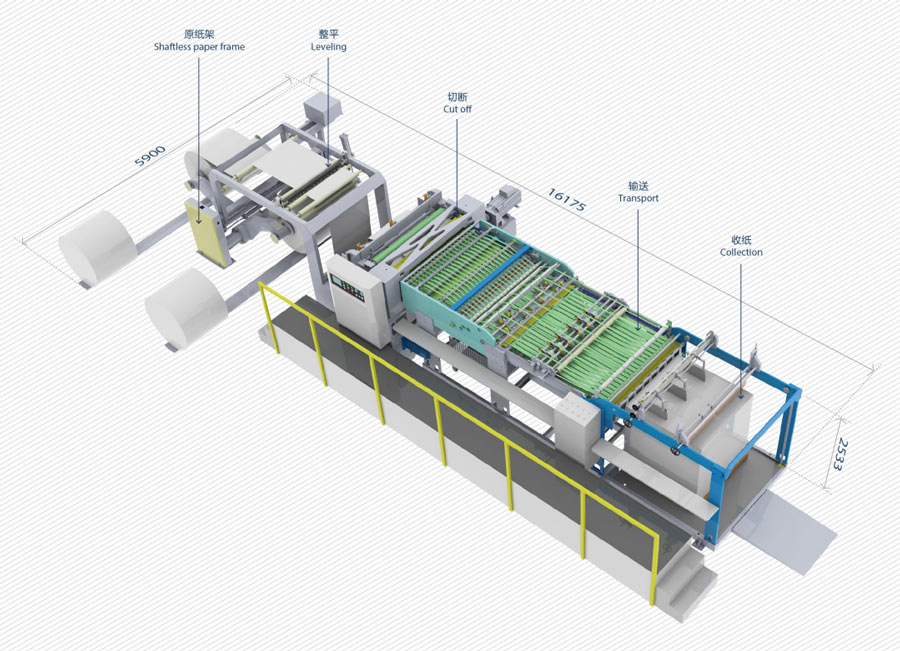

Mainly process including: Unwinding—Feeding—Cutting—Conveying—Collecting .

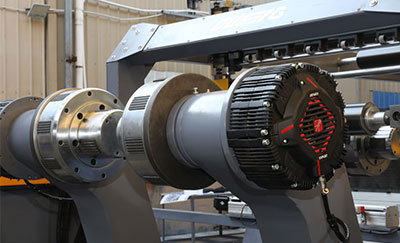

| Cutting Unit The double KNIFE cutting unit has a synchronic rotary cutting knife like scissors on the material to make a smooth and accurate cutting for paper from 150gsm and up to 1000gsm.The knife roller is using the most powerful driver from UK CT. Precision rotary sheeter groove is processed by imported advance processing center with high accuracy and stability, High quality gear box ,using no clearance design gear. which guarantees the stability of the tool body during high-speed operation, completely solve the problem of scratches and light spots, after cutting the edge is neat and smooth, clean cut. |

|

|

Double Arm Unwind stand with web tension controls and pneumatic brake units. Adopt Italian RE control system and pneumatic components are adopted to guarantee the stable operation of the brake control system and the accuracy of every aerodynamic action. |

| Three sets of MAXCESS pneumatic slitting knife ensure stable and clean slitting . High rigid tool post article can be applied to 400cut/min speed environment, improve the production efficiency and ensure the material quality stability. |

|

|

Electric control part Adopt German imports of Siemens PLC and UK OF CT servo drive control system, make the operation more convenient, automation, cutting length, number and the total number of finished products, etc., can be directly in touch screen input. High efficiency and energy saving of high power CT servo drive rotary knife shaft, and cooperate with the energy storage tank, effectively reduce electricity consumption, improve the efficiency, reduce the production cost. |

| Transportation parts Patent device-A precision structure can adjust the synchronous deceleration wheel, easy to operate, it is effective to protect surface of paper, so there will be no scratching on surface, and also will not have the facula whenever speed is high or low . |

|

|

The delivery section using automatic set paper equipment Lift stacked set paper , the paper stack to a considerable height, |

| Reject Gate In the end of the first conveyor belt is placed a sheet rejecting device, which can be inserted by the operator in the starting phase for the first sheets. The start of rejecting device is manual by pushing the ON.OFF button to act the air cylinder of reject gate. |

|

|

The new Anti curvature device (2 set de-curl ) Effectively remove the curl of the roll to make the paper more flat, more conducive the paper roll tension stability. |

1. Automatic Splicer

High performance automatic twin-head paper splicer with Taiwan control system, can splice paper aromatically, perform out by high flexilbility and long service life, suitable for base paper which grams of 80g/m²-400g/m².

2. Slitting & Trimming Knives Automatic Change System

APS-L series high-precision automatic positioning and slitting system matches high-precision sliting requirements. Intelligently, accurately and rapidly, the sliting and trimming knives is auto-changing by manipulator, thus greatly improving the ability and effciency when product variety changing. According to different cutting reguirements, it can work out different cuthing solutons by coordinating with different knife, such as automatic type, manual type, connected type and pressure cutting type slitting knife, and electronic knife, etc.

3. Platform Weighing Scalesystem

Material Weighing:The weighing scale installed at the lifting platform can display the weight of the paper stack timely for recording. t uses German technology and adopts four-horizontal and four-vertical structure to avoid scale damage and measurement errors caused by the displacement of paper stacks.

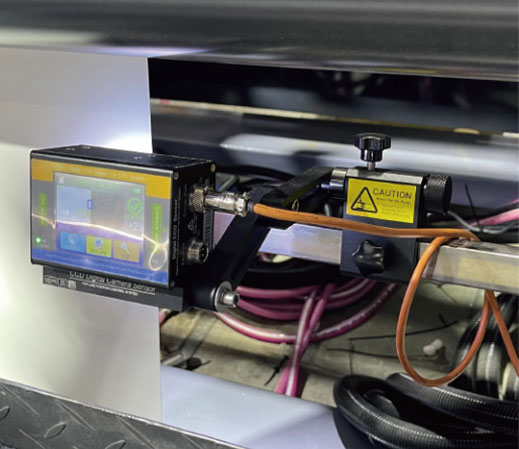

Stack Height Veasurement:The height of the paper stack can be measured by laser rangefinder. The laser sensor emits laser pulses, which are reflected back to the receiver by the stack, and it's height can be calculated by the fight time of the laser pulse or the amplitude ofthe photoelectric signal.

4. Infrared Align Auto-Adjustment

Paper Rolls alignment: the operator only needs to input the width in the touch screen, which can realize the auto-align-ment of the front and back paper rolls, avoid the loose and wrinkles caused by the wrong alignment, reduce waste. This system co-works with the order auto-changing system, and all controlled by servo motor. it adopts CcD correction sensor and supports EPC and LPC line tracking.

5. Color Code Sensor

The high precision detector, supplied by SlCK, a German brand, can accurately identify extremely fine color diferences with the sensing distance tolerance up to ±5mm.

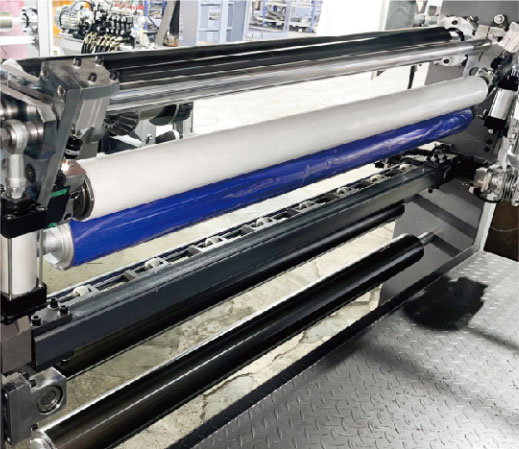

6. Dedusting Rollers

The blue high-viscosity roller can effectively adsorb the dust on the the paper, and then white dedust roller (driven by the cylinder) removes the dust on the bule. lt's easy to tear off the viscous film on the white one.

7. Pallet Pusher

The lateral pallet auto-pusher is developed independently by HAOSHENG. The servo motor drives the pushrod to push pallets from crossrange, thus gear up for collection.

8. Auto-Material Flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor, and uses the motor drive the material trans-port in ultra-low position straightly, which is a modular design and reach high degree of standardization. Hidden photo-electric switch can prevent photoelectric sensor or cardboard damage, servo motor built-in to save space, reversible operation, flexible adjustment, basically maintenance-free.

9. Inkjet Coding System (Inkjet Platform)

This part is composed of dedust system, high-speed inkjet system, intelligent positioning system, energy-saving LED curing system, image detecton system, data management system, high-speed waste removal svstem, tvpesetting software and printing software. Born for the packaging industry.

| ITEM | PARAMETERS | Cutting Length | Speed(m/min) | Speed (cuts/min) |

| Model | HSC 1500S/1700S/1900S | 1600≤X | 210 | <131 |

| Cutting Pattern | Double rotary sheeter | 1400≤X<1600 | 260 | ≥162<185 |

| Range of Gram Weight | 80-1000gsm | 1200≤X<1400 | 280 | ≥200<233 |

| Max.RollDiameter | 1800mm(71")Max | 1000≤X<1200 | 300 | ≥250<300 |

| Max.Paper Cutting Width | 1500mm/1700mm/1900mm | 800≤X<1000 | 300 | ≥300<375 |

| Total Power | 90kW | 700≤X<800 | 300 | ≥375<400 |

| Cutting Length | 400-1650mm | 650≤X<700 | 230 | ≥328<353 |

| Cutting Accuracy | +/-0.15mm | 600≤X<650 | 180 | ≥246<300 |

| Air Compressor Requirement | 0.8MPa | 550≤X<600 | 160 | ≥266<290 |

| Weight | 21000kgs/23000kgs | 500≤X<550 | 120 | ≥218<240 |

| Overall Dimension | L16175×W5900×H2533mm | 450≤X<500 | 90 | ≥180<200 |

| 400≤X<450 | 70 | ≥155<175 |

HSC1500S/1700S/1900S high-precision double-spiral slitting machine is a new product developed by our company using German technology and combined with many years of experience in producing paper cutters, which is high-precision, stable in operation, energy-saving and efficient. Widely used in cardboard, coated paper, kraft paper, cultural paper, offset paper, high-gloss photo paper, gold and silver cardboard, aluminum foil paper, laser paper, tobacco and wine packaging paper, etc.

The cutter roller adopts a double-rotating spiral cutter roller design, which has small cutting force, clean paper cross-section, high efficiency, and stable rotation; German precision bearings and cutting knives provide high cutting accuracy; light-touch computer interface control, easy to operate; well-designed feedback The curling device can effectively remove the curl of the paper roll, making the paper flatter, which is more conducive to the stability of the paper roll tension.

|

|

|

|

Roll to Sheet Paper Sheeting Machine is a device that converts large rolls of paper into single sheets of paper. It can also be called a paper roll cutter or paper roll cutter. This kind of machine is usually used in the paper processing industry, such as printing, packaging, paper manufacturing and other fields, to cut large rolls of paper into individual sheets of required specifications.

The working principle of the Roll to Sheet Paper Sheeting Machine is to feed large rolls of paper into the machine through an automatic feeding system, and then use a cutting device to precisely cut the paper roll, and finally cut the paper roll into single sheets of paper. Such machines typically have precise length control and cutting accuracy, allowing for efficient paper cutting operations.

Roll to Sheet Paper Sheeting Machines usually have a variety of functions and features, such as automated operation, high-speed cutting, precise positioning, easy adjustment and maintenance, etc., which can improve production efficiency, reduce labor costs, and ensure that the cut paper specifications are accurate.

When purchasing a Roll to Sheet Paper Sheeting Machine, you need to select the appropriate model and configuration based on production needs and paper specifications to ensure that the equipment can meet production needs and improve production efficiency.

Don’t know how to choose a sheet cutter? Master 4 hard metrics to avoid 90% procurement pitfalls. Haosheng (22-yr expert) offers precision/custom solutions with 1-yr...

In the realm of modern printing and packaging production, automatic paper sheet cutters stand as indispensable core equipment, and their paper type compatibility dir...

The right paper sheet cutter isn’t just a piece of equipment—it’s the backbone of consistent efficiency and product quality. Whether you’re handling packagin...

The printing industry thrives on precision—from the sharpness of text on a brochure to the alignment of graphics on a product box. Yet beyond ink and paper, another ...