How to Cut Multiple Sheets of Paper at Once: Efficiency Meets Precision

In industries ranging from printing and packaging to bookbinding and stationery manufacturing, the ability to cut large volumes of paper quickly and accurately is critical. Whether you’re trimming stacks of paper for brochures, creating uniform sheets for packaging, or preparing materials for mass production, manually cutting individual sheets is time-consuming, labor-intensive, and prone to inconsistencies. This is where advanced machinery like Paper Sheeting Machines and High Precision Sheet Cutters come into play, revolutionizing workflows for businesses that demand speed, accuracy, and scalability.

The Challenge of Cutting Multiple Sheets

Handling bulk paper cutting manually poses several challenges:

-

Time inefficiency: Processing hundreds or thousands of sheets individually drains productivity.

-

Inconsistent results: Human error can lead to uneven edges or misaligned cuts.

-

Material waste: Mistakes or imprecise cuts increase scrap rates and costs.

-

Safety risks: Repeated use of handheld tools raises the likelihood of workplace injuries.

To overcome these hurdles, businesses are increasingly turning to industrial-grade equipment designed to cut multiple sheets of paper at once—safely, precisely, and efficiently.

The Solution: Paper Sheeting Machines and High Precision Sheet Cutters

Modern paper-cutting technology has evolved to meet the demands of high-volume operations. Below, we explore two essential types of equipment that enable simultaneous multi-sheet cutting:

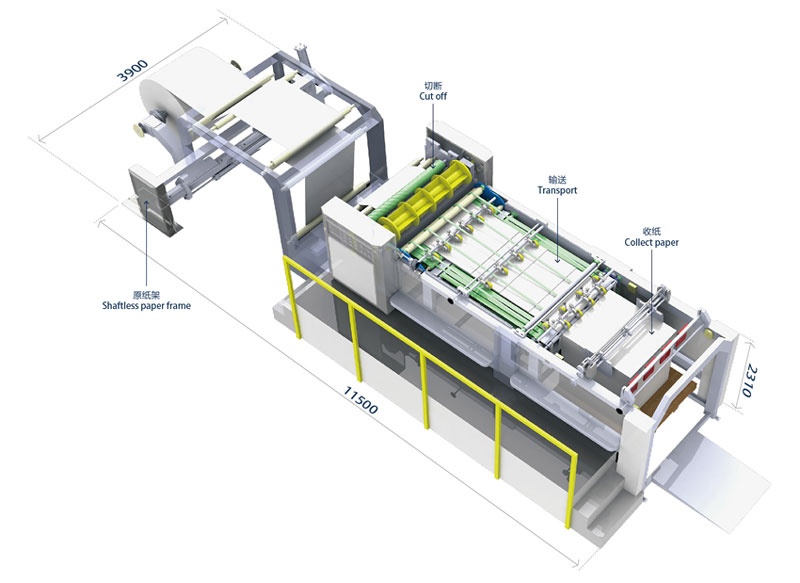

1. Paper Sheeting Machines

A Paper Sheeting Machine is engineered to convert large rolls of paper into perfectly sized sheets at remarkable speeds. These machines are ideal for industries requiring bulk processing, such as packaging or commercial printing. Key features include:

-

Automated feeding systems: Seamlessly unwind and feed paper rolls into the cutting mechanism.

-

Programmable cutting lengths: Adjust settings digitally for custom sheet dimensions.

-

Multi-layer cutting: Capable of slicing through entire rolls into hundreds of uniform sheets in a single pass.

-

Integration with workflows: Often paired with stackers or conveyors for end-to-end automation.

By eliminating manual handling, paper sheeting machines reduce labor costs while ensuring consistent output for high-volume orders.

2. High Precision Sheet Cutters

For businesses that require ultra-accurate cuts on pre-cut sheets, High Precision Sheet Cutters are the gold standard. These heavy-duty machines excel at trimming stacks of paper, cardboard, or laminated materials with micron-level accuracy. Advantages include:

-

Hydraulic or electric cutting systems: Deliver powerful, clean cuts through dense stacks (often 100+ sheets at once).

-

Laser-guided alignment: Ensure perfect positioning to avoid misaligned edges.

-

Adjustable pressure settings: Optimize blade force for different materials and thicknesses.

-

Safety features: Integrated guards, emergency stops, and sensors protect operators.

High precision cutters are widely used in premium printing, luxury packaging, and precision engineering industries where even a millimeter’s deviation is unacceptable.

Benefits of Industrial-Grade Paper Cutting Equipment

Investing in specialized machinery like paper sheeting machines or high precision cutters unlocks transformative advantages:

-

Massive productivity gains: Cut hundreds of sheets in minutes versus hours of manual work.

-

Cost savings: Reduce labor, minimize waste, and extend blade life with optimized cutting cycles.

-

Enhanced quality: Achieve flawless edges and dimensions, critical for client-facing products.

-

Scalability: Handle growing order volumes without compromising turnaround times.

-

Worker safety: Automated systems reduce physical strain and blade-related risks.

Applications Across Industries

-

Printing & Publishing: Trim book pages, flyers, or catalogs in bulk.

-

Packaging: Create custom-sized boxes, inserts, or labels from corrugated or laminated sheets.

-

Stationery & Office Supplies: Produce notepads, sticky notes, or file folders with uniform edges.

-

Art & Design: Cut specialty papers for high-end invitations, portfolios, or displays.

Choosing the Right Machine for Your Needs

When selecting equipment, consider factors such as:

-

Material type and thickness (e.g., bond paper, cardstock, or corrugated board).

-

Volume requirements (daily output targets).

-

Cutting precision (tolerances needed for your products).

-

Automation compatibility (integration with existing production lines).

Reputable manufacturers often provide customizable solutions tailored to specific workflows.

Conclusion: Elevate Your Production with Advanced Cutting Technology

In today’s competitive market, efficiency and precision are non-negotiable. By leveraging industrial solutions like Paper Sheeting Machines and High Precision Sheet Cutters, businesses can streamline operations, reduce costs, and deliver superior-quality products consistently. Whether you’re upgrading an existing facility or scaling a startup, investing in multi-sheet cutting technology is a strategic move to stay ahead.

Ready to transform your paper-cutting process? Explore cutting-edge machinery from trusted suppliers and unlock the potential of bulk processing today.